Thread Rolling is a highly versatile cold forming process which can be done on any type of ductile metal to harden, strengthen, or change the material’s physical properties in other ways.

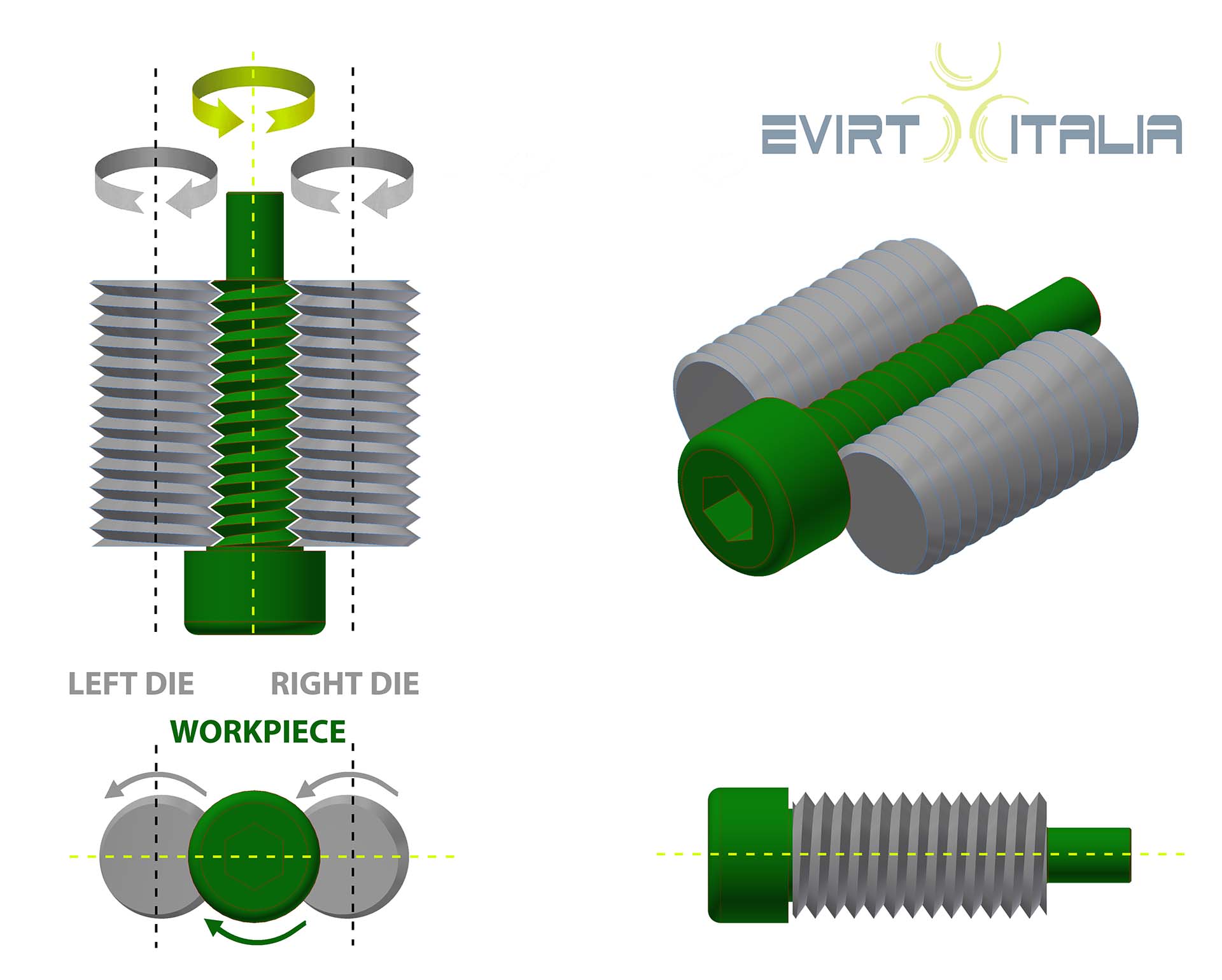

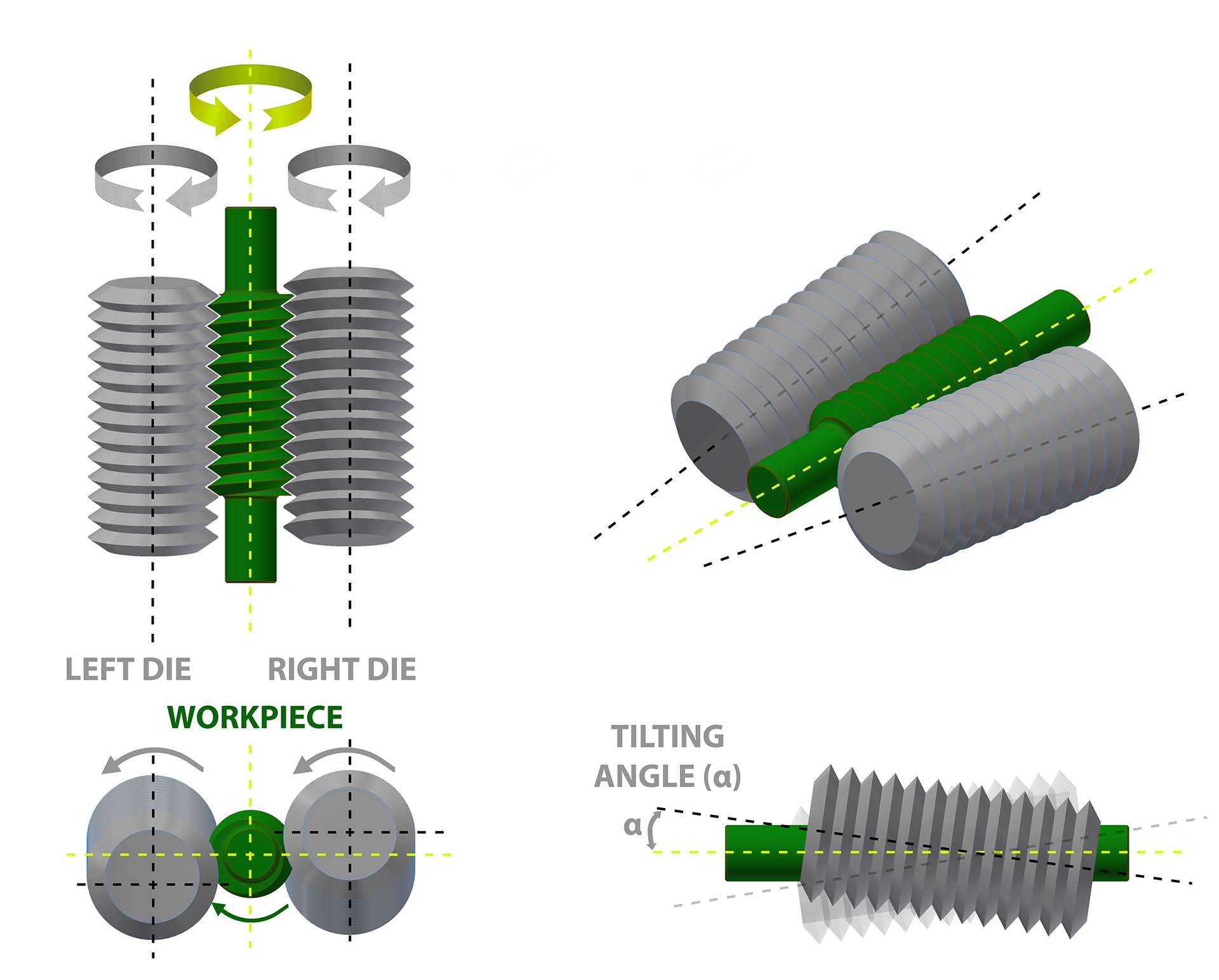

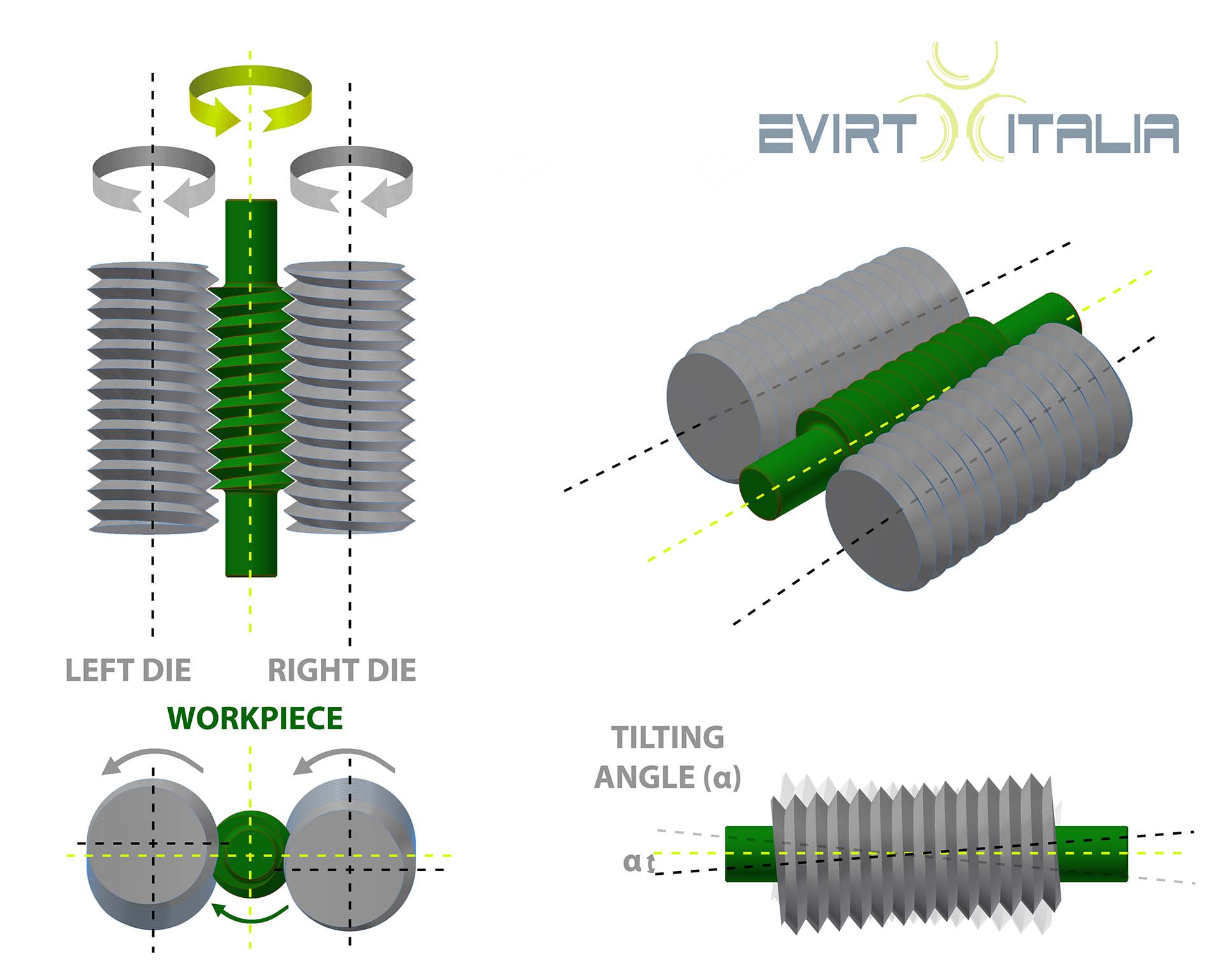

Thread Rolling makes use of hardened steel cylindrical dies to shape materials; the dies, imprinted with the thread profile, penetrate the work metal at ultra-high pressures in order to displace and mold it into a mirror-image thread. Unlike traditional cutting and grinding methods, no metal is lost or cut away during the thread rolling process; it is simply reshaped.

The main functionality of Thread Rolling is represented by a component pressed in rotation by two or three rolling dies installed on two or three rolling heads (slides). At least one rolling slide has a feed movement to perform the forming process which simultaneously moves in contact with the workpiece while dies are rotating synchronously, whereas the profile will be formed out.