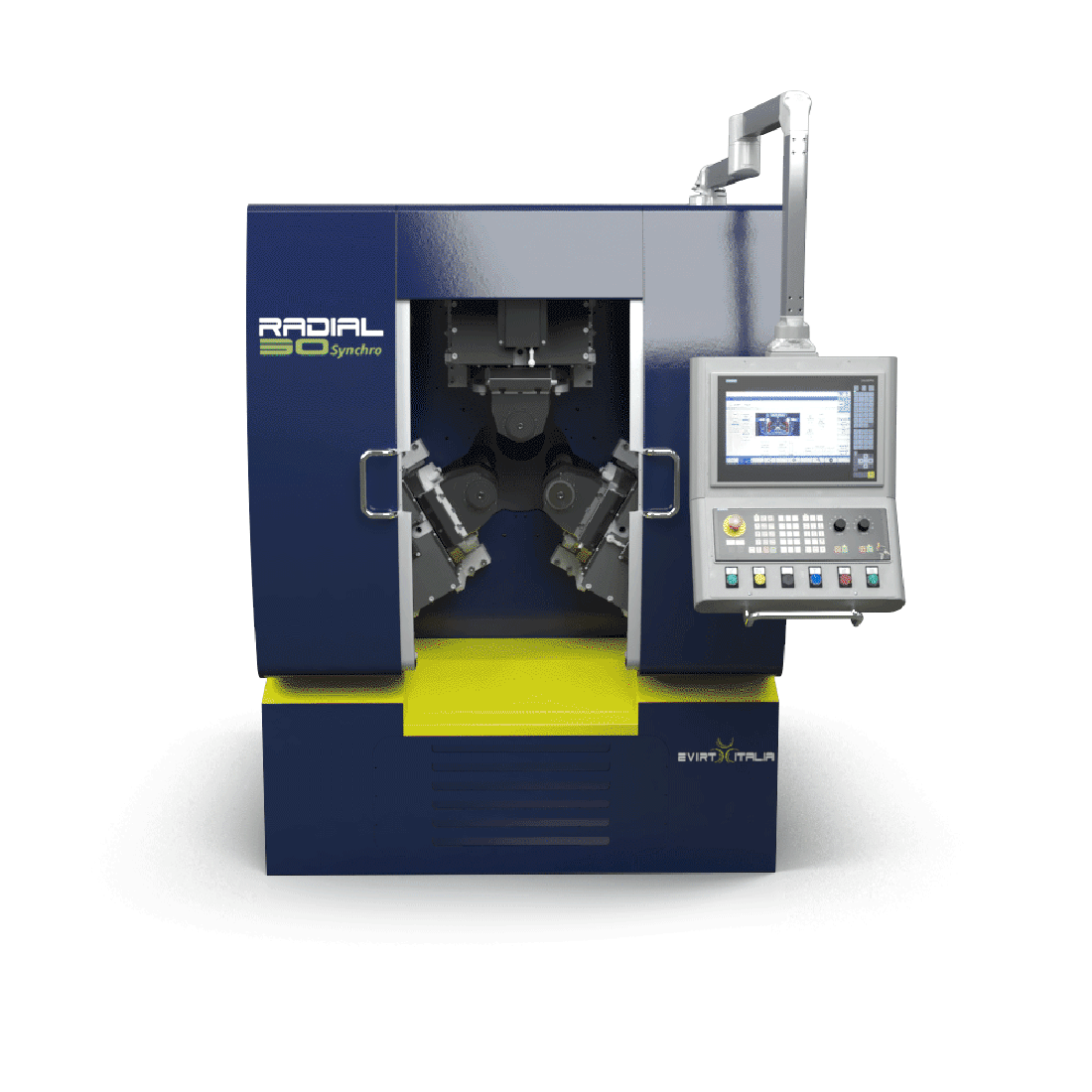

- Dynamically high stiff H-frame MONO Block machine, electro-welded and passed into oven to distribute the welding contractures; YouTube

- No screws’ connection between the main frame and the rolling heads (linear slides);

- Frame’s Thickness increased around 400% respect to market available machines ensuring a much higher frame’s stiffness and thus the machine’s resistance to react the rolling force. Thanks to this the improvement, the machine’s deflection under its maximum working force has been reduced to 3 microns compared with the 0,2 mm deflection measured on standard machines versions – “zero deflection concept”.

- Reinforced base Frame’s plate: designed to provide an opposite resistance component to the rolling force; what’s more, being the distance between the reaction force and the rolling zone much higher than the distance between rolling area and working plan, the torque resistance is much higher and provide another further support to avoid the machine’s deflection.

- Rolling Force ranging from 100 kN to 1500 kN.

- Rolling Diameter from 2 up to 300 mm.

Machine’s control system developed from the analysis of users experience to satisfy the requests of precise and fully independent rolling machines:

- Auto-calculation of working parameters.

- Intuitive and Quick changeover.

- Automatic Pitching Research on new tools – PATENT PENDING

- Magnetic Blocking System of Spindles’ Inclination –PATENT PENDING

- Fully approved 4.0 Machine’s Managing Control. YouTube

- 4.0 Power Saver Hydraulic System. YouTube

- Easy use of EVIRT INTUITIVE HMI suitable to control the machine as well as all its integrated automation.

- Graphical user interface including Process visualization and User Guidance.

- Process data management.

- High accessibility to rolling area for any kind of loading and unloading activity.

- Central lubrication.

- Quality monitoring of stroke, force, torque and axial movement.